Discovering the Uses and Advantages of Recycled Composites in Modern Industries

In today's swiftly progressing industrial landscape, the use of recycled composites has actually gathered boosting attention for its possible to redefine standard manufacturing methods. The combinations of recycled materials with advanced composite technologies presents an appealing method for improving sustainability, durability, and cost-efficiency throughout various fields. As industries seek ingenious services to deal with ecological issues and enhance functional efficiencies, the consolidation of recycled compounds becomes a compelling alternative. This change towards lasting practices not just lines up with global conservation efforts however additionally provides a myriad of benefits that hold the trick to forming the future of contemporary manufacturing methods.

Environmental Benefits of Recycled Composites

The application of recycled compounds in modern-day industries supplies significant ecological benefits, contributing to the decrease of waste and the conservation of natural resources. By including recycled composites into producing procedures, industries can lower their dependence on virgin products, therefore reducing the amount of waste generated and the power required for extraction and manufacturing. This shift in the direction of using recycled composites assists in drawing away products from garbage dumps, alleviating the burden on waste management systems, and reducing greenhouse gas emissions connected with conventional manufacturing methods.

In addition, the usage of recycled composites promotes the preservation of natural sources such as wood, minerals, and water, which are typically depleted via the extraction and handling of resources (composites). By expanding the lifespan of materials via recycling, sectors can help preserve communities and biodiversity by lowering the demand for new sources. Overall, the fostering of recycled compounds in modern-day sectors plays an important function in promoting sustainability and alleviating the ecological influence of manufacturing processes

Enhanced Durability in Product Production

With a concentrate on durability and effectiveness, incorporating recycled compounds into product production procedures enhances longevity and sustainability. By making use of recycled composites, producers can create products that are not just solid however additionally resistant to tear and put on, making them suitable for lasting use in various sectors. The mix of different materials in recycled composites can typically lead to boosted toughness and durability contrasted to typical products, supplying a cost-effective remedy for creating resilient items.

One of the key advantages of making use of recycled compounds in item production is the capacity to customize the product buildings to satisfy certain resilience needs. By changing the structure and production methods, manufacturers can tailor the recycled composites to hold up against extreme environmental problems, heavy loads, or constant usage without endangering on performance. This flexibility in layout and manufacturing permits for the development of very long lasting products that keep their honesty with time, minimizing the requirement for constant substitutes and inevitably adding to a much more sustainable production process.

Cost-Effectiveness and Economic Advantages

Integrating recycled composites into item manufacturing not just boosts sturdiness and sustainability however additionally uses significant cost-effectiveness and economic advantages. Utilizing recycled compounds can lead to minimized material prices as recycled products are commonly more economical than virgin materials. Additionally, reusing composite materials can reduce garbage disposal expenditures and reduce the requirement for garbage dump room, contributing to overall price financial savings for sectors.

Advancement and Layout Flexibility With Recycled Compounds

Making use of recycled composites in modern-day industries provides unparalleled opportunities for innovation and layout versatility. By including recycled products right into composite read what he said manufacturing procedures, firms can press the borders of typical layout restraints and discover new opportunities. The adaptability of recycled composites enables the creation of complicated forms and structures that might not be possible with standard products.

One of the essential benefits of recycled compounds is their ability to be built into numerous forms, giving developers the freedom to experiment with special sizes and shapes. composites. This versatility opens up a world of innovative chances, enabling the advancement of light-weight yet durable items that meet the specific demands of various sectors

Furthermore, using recycled composites advertises lasting techniques and supports the round economy by minimizing waste and minimizing the environmental effect of producing procedures. This concentrate on green design solutions aligns with the expanding trend in the direction of sustainability in contemporary sectors, making recycled composites an important resource for forward-thinking and ingenious business.

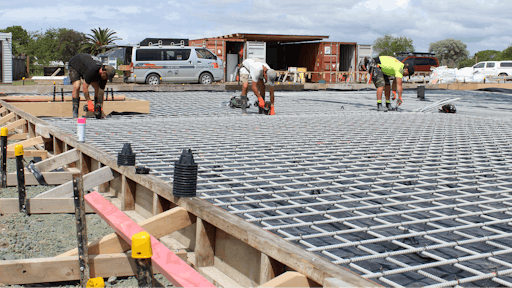

Applications Across Various Industries

Recycled compounds find diverse and impactful applications across a wide variety of markets due to their unique residential properties and sustainability advantages. In the vehicle field, these materials are progressively made use of for producing resilient and light-weight elements, boosting gas effectiveness and minimizing carbon emissions. The aerospace industry gain from recycled compounds in the production of aircraft components, where the materials' strength-to-weight proportion is essential for guaranteeing safety and security and efficiency. In building and construction, these compounds are used for producing strong yet environment-friendly building materials, contributing to lasting facilities growth. The renewable resource field utilizes recycled compounds in wind turbine blades and solar panels, utilizing their strength and resistance to extreme environmental conditions. In addition, the aquatic market uses these materials for manufacturing boat hulls and parts, supplying enhanced toughness and rust resistance. The adaptability and sustainability of recycled compounds make them useful across numerous industries, driving technology and environmental stewardship. composites.

Verdict

Finally, the usage of recycled composites in modern-day industries uses considerable ecological advantages, enhanced longevity in product manufacturing, cost-effectiveness, and economic her response benefits. Furthermore, making use of recycled composites enables advancement and style adaptability throughout numerous industries. Generally, the fostering of recycled composites presents a lasting and practical remedy for fulfilling the needs of the market while also minimizing ecological effect.

One of the crucial benefits of making use of recycled compounds in item production is the ability to tailor the material homes to meet particular sturdiness demands. Utilizing recycled composites can lead to minimized material prices as recycled products are frequently less expensive than virgin products. The aerospace market advantages from recycled compounds in the manufacturing of airplane components, where the materials' strength-to-weight proportion is critical for making certain sites security and efficiency.